Tanbreez is a producer of rare earth elements with minimal waste and carbon emissions. The company states that it can use up to 97% of its mine waste, thereby reducing its CO2 emission substantially.

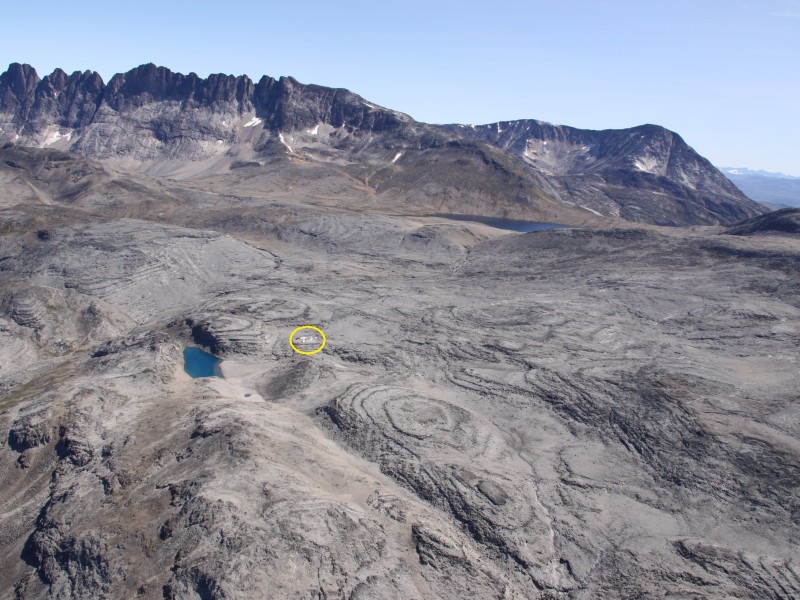

It is proposing to start a mining project in Greenland. By producing essential metals crucial for environmental clean-up, the company plays a vital role in fostering sustainability.

The proposed Tanbreez project in Greenland is set to enable a massive reduction in CO2 with as much as 97% mine waste to be commercially utilized, says Founder and Geologist Greg Barnes.

Using up to 97% of mine waste

The Tanbreez project is unique when compared to most other rare earth projects in that it only contains background values of uranium and thorium. Unlike other nearby projects in Greenland, the Tanbreez project does not contain other contaminants which also occur nearby such as soluble fluorine, soluble phosphate, thallium, lead, and the daughter radioactive products such as radon and actinium.

Extensive research has indicated the potential to sell as much as 97% of the mined material, leaving a mere 3% as waste, thereby minimizing the waste volume significantly. It may also be possible to use this minimal 3% waste as landfill, road base etc. as it is inert.

What does Tanbreez produce?

Praseodymium, neodymium, terbium, and dysprosium belong to the group of four rare magnetic earth elements and are crucial components in windmills, electric or hybrid cars, and various motors, including those used in compact devices like watches and computers. These elements are responsible for generating the most powerful magnets employed in these applications.

Other rare earths such as cerium and lanthanum can be used to increase the efficiency in burning of hydrocarbons. While lutetium has the potential for the development of super conductors.

In addition to rare earth elements, the company will also manufacture tantalum, which is utilized in microchips, telephones, and even for creating replacement body parts. Furthermore, they will produce zirconium, a vital material for nuclear casings and metals used in fuel cells (used to make hydrogen), as well as hafnium for nuclear fuel rods. Additionally, the company will be involved in the production of niobium and various industrial products.

Local Employment

The company has signed an agreement with the local community, Kommune Kujalleq, to assist with employment and training of local personnel. Both agree that it may be possible to employ 90-95% local personnel.

The initial workforce is projected to consist of around 80 employees, with the potential to increase to 240 should the extension to 3 million tons per year be approved based on market demand and other factors. During the mine’s initial stages, there may be a need to recruit offshore personnel with relevant experience to operate and maintain machinery.

However, the company has a track record of demonstrating that with proper training, local experts can successfully undertake numerous roles. For instance, the company’s previous drilling program predominantly engaged personnel from the local mining school who performed admirably.

Future plans

Initial production will be for 0.5 million tons per year through put. However plans are afoot to seek permission to extend that to 3.0 million tons per year by year 5, pending the relevant approvals being obtained. The mine would be capable of expansion beyond that as further markets are expected to be opened up in Europe and for the far east.

Initially products will be created for the North American market although with the potential for further increases in through put with future markets in Europe and Asia.

For further information please visit: https://tanbreez.com/

About Tanbreez:

Greg Barnes: Founder & Principal Geologist

Bolette Nielsen: Chairperson & Greenland Office Manager

Christopher Messina: Chief Executive Officer

Bill Cassidy: Chief Financial Officer

Anna Wingell: Director & Perth Office Manager